Future supermarket refrigerated retail display cabinets

The design of retail display cabinets has predominantly been the same for many years. Manufacturers have tweaked air curtains, adjusted air flows and added air guides. More recently the major development has been to add doors to open fronted chilled cabinets which is a growing trend.

RD&T have recently hosted work on a novel chilled cabinet as part of the ENOUGH project (https://enough-emissions.eu/). The work carried out by the Heating and Cooling team at London South Bank University (LSBU) used the facilities at RD&T to test and optimise the performance of a novel display cabinet. The work focused on optimising an advanced display cabinet based on best available technologies (BAT). The technologies included were short air curtains, doors, proximity sensors and reflective packaging.

Chilled refrigerated display cabinets with open fronts rely on a fan-driven air curtain. This technology enables easy access for customers, while forming a barrier to the exchange of air. The aim of using the front air curtain is to minimise entrainment of the warm “moist” room air and protect the temperature of the products that are located at the front of the shelves. The air curtain is not perfect and causes entrainment into the chilled cabinet area mainly through turbulent mixing. As the length of the air curtain increases, so does its temperature and its ability to keep product cold at the bottom of the cabinet. A longer air curtain requires a higher flow rate to reduce this problem, increasing turbulent mixing. Short air curtains for open, vertical refrigerated display cabinets have been reported to provide between 25 and 36% reduction in total energy consumption compared to a display cabinet with a conventional curtain (Hammond et al., 2016[1] and Pitchers et al., 2018[2]).

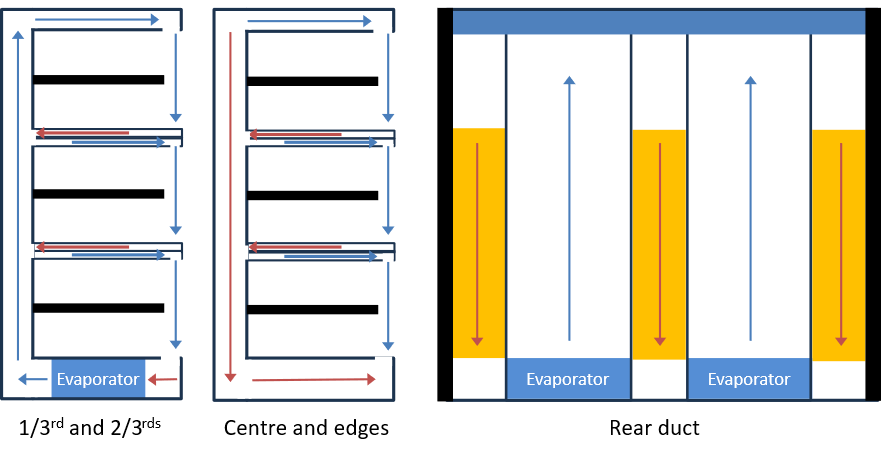

A cabinet was adapted to incorporate short air curtain technology. This involved shelves which incorporated vaned ducting to allow cold air to exit the shelves, forming sequential air curtains, and air to be returned to the evaporator to be re-cooled. To do this required the cabinet to be split into different sections along its length such that air could be delivered to the air curtains and returned to the evaporator.

The cabinet was tested and developed in an EN23953 test room at RD&T. The cabinet was operated from RD&T’s R744 (carbon dioxide) refrigeration system. With the short air curtains, the cabinet achieved the M1 (-1 to 5°C) temperature classification at climate class 3 (25°C and 60% relative humidity test room conditions). The cabinet temperature range was 5.3 K which is very low for an open fronted cabinet in climate class 3 conditions.

Adding double glazed, hinged doors had a great benefit to the cabinet, allowing the evaporating temperature to be increased significantly to -2.8°C limiting the need for defrosts when the cabinet was running at the M0 (-1 to 4°C) temperature classification. At this temperature classification the temperature range was only 4.2 K. The energy efficient index (EEI) which is used for energy labelling was 17.3 (energy class B) which is class leading for a 2.5 m supermarket cabinet. Running the cabinet at the higher temperature classification of M2 (-1 to 7°C) allowed the evaporating temperature to be increased to 0°C eliminating the need for defrosts.

When adding reflective packaging it was found that the benefits were unlikely to outweigh the costs and carbon emissions associated with the packing. However, there would be a significantly greater benefit for freezer cabinets.

The benefits of sensors to turn lights off when customers are not present obviously depends on the level of customer footfall. In tests where a typical usage was applied the results demonstrated small but significant energy savings. For a technology that requires minimal costs to apply this is worth considering.

If you would like to see a video of the work, it can be accessed via YouTube at: https://www.youtube.com/watch?v=oRCgVw2wtYk

If you would like further information on this work or would like to discuss how we could test or develop display cabinets, then please do give us a call. We have extensive experience in helping to improve products and have the test facilities to test performance. Contact either Judith Evans (j.a.evans@rdandt.co.uk) or Alan Foster(alan.foster@rdandt.co.uk).

[1] Hammond, E., Marques, C. and Ketteringham, L.P., 2016. Application of short air curtains in retail display refrigerators. Refrigeration Science and Technology, 2016, pp.49-56.

[2] Pitchers, S., Marques, C., Rees, R., Cooper, R. and Hammond, E., 2018. Performance comparison between shorter and conventional air curtains in retail display refrigerators. Refrigeration Science and Technology, 2018, pp.215-224.