Scope 3 emissions – importance in the food and drink industry

The food and drink (F&D) sector has had many challenges over the past decade. Brexit, closely followed by COVID-19 as well as the cost-of-living crisis, the high cost of energy and increased costs of staff have significantly affected F&D businesses. Longer term challenges also exist such as the impact of climate change and the pressure to decarbonise to contribute towards net zero.

Many F&D organisations, and especially the trade bodies that represent them, have net zero targets. Usually, these plans are presented as roadmaps to reduce scope 1, 2 and 3 emissions (see Annex for more details).

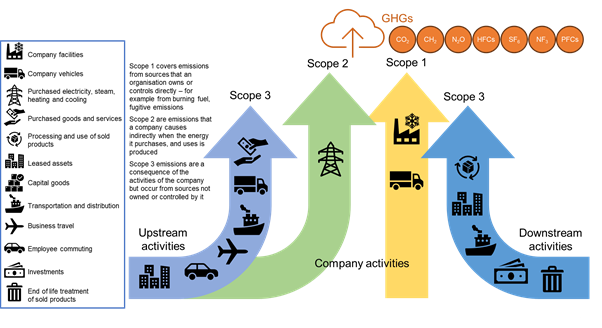

Many manufacturers are aware of their scope1 (direct fuel and refrigerant emissions) and scope 2 (mainly electrical energy) emissions as they have direct control over these. However, there is a growing demand by supermarkets and food service operators to have knowledge of their scope 3 emissions (arising from consequence of the activities of the company but from sources not owned or controlled by it). This is then passed back up or down the chain to be provided by producers, manufactures and logistics companies.

Organisations such as the Science Based Targets initiative (SBTi) provide standards, tools and guidance to help companies reduce emissions aligned to the Paris Agreement (which aims to limiting global warming to 1.5°C above pre-industrial levels). SBTi provide a Corporate Net-Zero Standard (SBTi) which is currently being updated and helps companies define their decarbonation strategies and targets.

If you are an equipment manufacturer that supplies the F&D sector, then you need to consider the scope 3 emissions from your suppliers and the emissions from the use of your sold products. You can reduce your emissions from sold products though making them more efficient and making sure that they are used in the most efficient manner. Usually this would be through reducing electrical energy consumption and reduced emissions from refrigerant leakage.

For some equipment there is existing pressure to reduce emissions through energy labelling and/or f-gas regulation. However, there are still many types of equipment that do not fall under either energy labelling or f-gas regulations. Some of this equipment does not even have recognised standards by which to measure and compare energy consumption. It is possible that this equipment may fall into these regulations in the future but the current demands to provide scope 3 emissions data may also drive this equipment to greater efficiencies and lower emissions. RD&T often develop test methodologies and measure performance of equipment for manufacturers which helps provide this data (see: test standard development)

One thing that is clear is that it is no longer possible to ignore the emissions of equipment once it is sold. This presents opportunities for forward thinking manufacturers who produce energy efficient equipment that competes favourably with less efficient alternatives. If you are a manufacturer or user of F&D equipment and interested in lower emissions, then please contact Alan Foster at RD&T (alan.foster@rdandt.co.uk).

Annex

Scope emissions are a way of categorising greenhouse gas (GHG) emissions based on where they originate within a company's value chain. The three main scopes are: scope 1 (direct emissions), scope 2 (indirect emissions from purchased energy), and scope 3 (other indirect emissions across the value chain).

Categorising these emissions into scopes 1, 2, and 3 allows companies to understand their complete carbon footprint and focus on the most significant reduction opportunities. By breaking down emissions, companies can identify where they can have the greatest impact on reducing their overall carbon footprint.

Scope 1 emissions

As these emissions are direct from sources owned or controlled by the company, they are perhaps the easiest to focus on first. In the food retail/service sector, these emissions are most likely to come from burning of fossil fuels for space heating, food heating, or transportation.

In food heating and cooking, scope 1 emissions can be completely removed, by moving from fossil fuel, e.g. natural gas ovens to electric ovens and for space heating, from natural gas boilers to heat pumps.

This, however, does not remove the emissions, but moves them from scope 1 to scope 2.

Scope 2 emissions

These are indirect emissions, where the emission occurs elsewhere. The biggest source of scope 2 emission in UK food retail/service, is likely to be from electricity, where the emission occurs at the power station. The UK electrical grid is rapidly decarbonising to renewable sources, mainly wind and solar, so that GHG emissions per kWh of electricity are likely to reduce year on year, without any intervention from the food retailer.

Businesses can reduce their emissions faster by purchasing renewable energy from their electricity provider or by having their own photovoltaic panels (PV) on their facility roofs.

Scope 3 emissions

These emissions are the most difficult to address, as they represent all indirect emissions in a company's value chain that are not already included in scope 1 or scope 2. For this reason, they have not been the primary focus. However, large food retailers, e.g. supermarkets and fast-food chains have often measured their scope 1 and 2 emissions and are now focussing on their scope 3 emissions.