Professional refrigeration labelling and Eco-design review

Energy labelling and Ecodesign regulations for professional refrigerated storage cabinets entered into force in July 2016. Since then, the lower energy label classes (G and F) have been banned. A review study is currently being carried out to review Commission Regulation (EU) 2015/1095 (Ecodesign of professional refrigeration products) and Commission Delegated Regulation (EU) 2015/1094 (Energy labelling of professional refrigerated storage cabinets). This follows the requirement within the regulations to review them in the light of technological progress no later than five years after they enter into force. The draft technical analysis study is now available (https://www.ecoprorefrigeration.eu/documents.htm). An initial stakeholder meeting was held at the start of the study with another meeting planned for October 2021 and a consultation forum meeting planned for March/April 2022.

In particular, the following issues are considered for professional refrigerated storage cabinets and blast chillers:

- Ecodesign requirements for cabinets. This includes assessing the currently included cabinets, plus assessment of currently excluded categories (including static air cabinets, roll-in and pass-through cabinets, refrigerator freezers, professional ice makers, water dispensers, dessert and beverage machines and laboratory grade refrigerators and freezers).

- Stricter requirements for heavy-duty cabinets.

- Information requirement on the capacity for a professional refrigerated storage cabinet to cool down foodstuffs.

- A method for determining the standard annual energy consumption for refrigerator-freezers.

- A revised method for the standard annual energy consumption of counter cabinets.

- For blast cabinets, introducing Ecodesign requirements and whether remote condensing unit options could/should be included in the regulations.

In addition, changes in market share for various appliances, assessment of verification tolerances, equivalence between test standards and clarifications to the regulations are considered.

The report states that both sales and stock of professional cabinets have increased continually since 1990 and are forecast to continue increasing to 2050. Compared to 2015, Ecodesign and energy labelling resulted in a 13% energy efficiency improvement in 2020 and this is forecast to continue increasing to a 40% improvement in 2030.

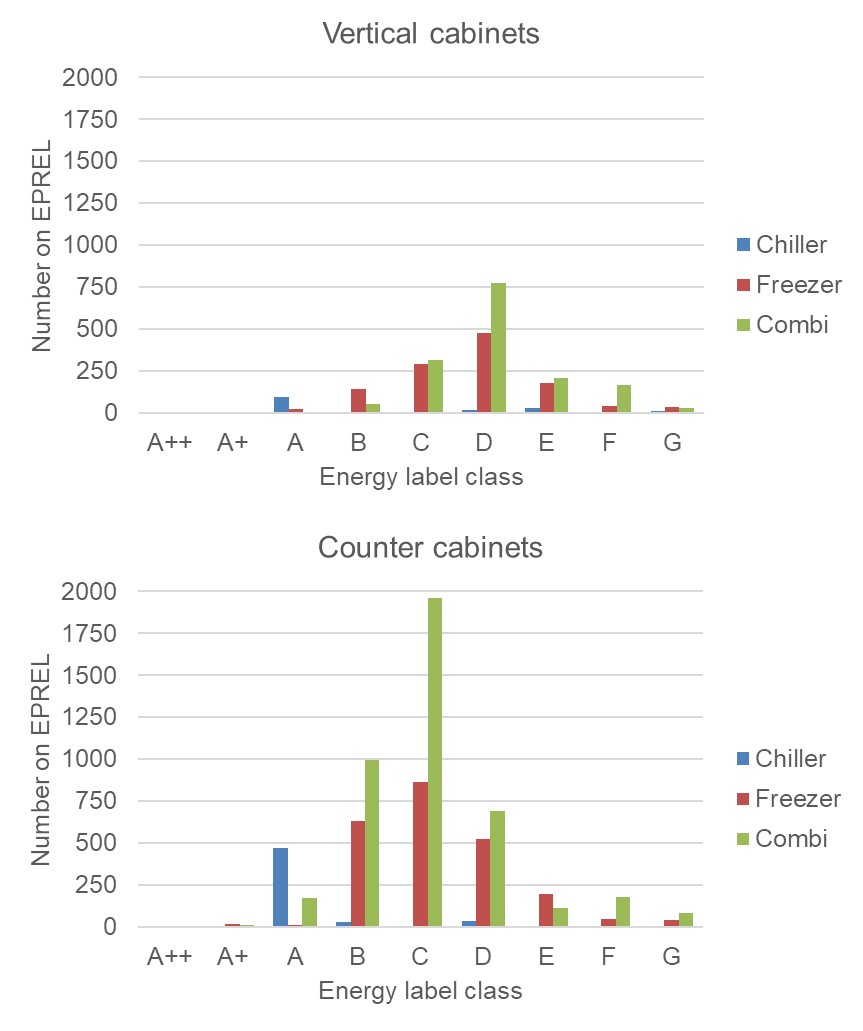

There are several issues that have been identified with the current regulations. Both upright and counter chiller cabinets receive more favourable energy labels than equivalent freezers. Small volume chillers are especially favoured due to the relationship between volume and energy consumption being relatively neutral. Counter chillers are especially favoured, e.g. a chilled counter uses the same energy at almost 0 volume as a vertical chilled does at 900 litres. This means that is much simpler for a counter chiller to achieve a good energy label than other professional refrigerators. This is borne out in the data from the EPREL which shows that there are far more smaller volume counter cabinets with high efficiency energy labels (see graphs below).

The concession allowed for heavy duty cabinets no longer appears to be useful. Topten assessed the market and found that 90% of models were already classed as ‘heavy duty’. This is borne out in several of the position papers submitted by interested parties who also state the concession is no longer relevant. Position papers also state the professional cabinets are not designed to cool products and that blast chillers should be applied for this purpose.

If you would like further information on Ecodesign or energy labelling of refrigerated products then please contact Judith Evans at RD&T (j.a.evans@rdandt.co.uk).